S1406 Solid Carbide nACo Coated Upcut Spiral Router Bit - 2 Flutes - 1/4 SD - 1/4 CD - 1-1/2 CL - 3 OL

S1406 Solid Carbide nACo Coated Upcut Spiral Router Bit - 2 Flutes - 1/4 SD - 1/4 CD - 1-1/2 CL - 3 OL

Available in stock

| Rotation | Upcut | Coating | nACo |

|---|---|---|---|

| Shank Diameter | 1/4" | Router Bits Types | 1/4" Shank Spiral Bit |

| Cutting Diameter | 1/4" | Product Series | X-Series |

| Cutting Length | 1-1/2" | Cutting Edge Type | Solid Carbide |

| Overall Length | 3" | Measurement | Imperial |

| Flutes | 2 | Machinery Type | Handheld Router, CNC Router, Router Table |

| Material | Hardwoods, Softwoods, Laminate, Melamine, Plywood, MDF, Chipboard, Foamcore, Light Board, Aluminum Foamcore, Veneered Plywood, Particle, OSB, Solid Surface Material, Plastic, Acrylic | ||

| Rotation | Upcut |

|---|---|

| Shank Diameter | 1/4" |

| Cutting Diameter | 1/4" |

| Cutting Length | 1-1/2" |

| Overall Length | 3" |

| Flutes | 2 |

| Coating | nACo |

Why Choose Spiral Router Bits Instead of Straight Bits?

- Spiral router bits combine a shearing action with an augering action for chip clearance. This dual action not only produces a clean and accurate cut but also efficiently clears chips from the cut area, enhancing the overall cutting experience.

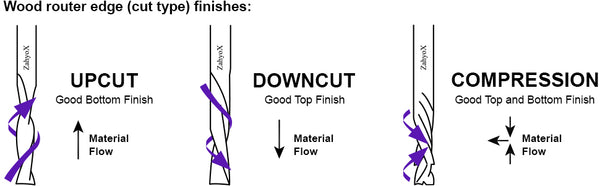

What is Up-Cut Bits?

- Features: The ‘Up-Cut’ shears from the bottom up pulling chips from the bottom up thus allowing deeper penetration and rapid cutting with less stress on the tool.

- Applications: Best used in applications requiring clean finishes on the bottom surface, like grooving or deep cutting.

- Considerations: Risk to Top Surface: The upward action may damage the top layer, making them unsuitable for projects where top appearance is critical.

What is nACo Coating?

nACo, or nano-composite coating, is a micro-thin ceramic coating applied to cutting tools. Zahyox X-Series bits feature a nACo coating with extreme hardness and heat resistance. With a blue-tinted coloring, nACo enhances their performance and durability in router tooling.

- Sharpness Retention: Maintains cutting edges razor-sharp for precise and clean cuts.

- Reduced Friction: Features an extremely low friction coefficient of 0.25, minimizing tool wear and facilitating smoother operations.

- Heat Resistance: Can withstand up to 900°F, protecting tools from heat damage during intense cutting tasks.

- Enhanced Durability: Delivers a hardness of 3800 HV, which increases resistance to wear and extends 3 times longer tool life.

Why Choose ZahyoX Router Bits?

- Geometry Specs: 1/4" Cutting Diameter, 1/4" Shank, 1-1/2" Cutting Length, 3" Overall Length, 2 Flutes, Up-Cut Spiral, Nano Coated.

- Industrial-Grade Solid Carbide: ZahyoX is an industrial manufacturer, making solid carbide material and solid carbide router bits our sole business for over two decades, we make our products like creating art.

- Excellent for Cutting: Perfect for CNC sizing, cutting, and routing laminate, melamine, plywood, MDF, chipboard, foam-core, light board, aluminum foam-core, carbon fiber, veneered plywood, and solid surface material.

- Perfected Geometry Design: The geometry design has been iterated hundreds of times to ensure a perfect balance between tool life and cutting efficiency. We run our bits systematically on various machines and materials to test the performance of each iteration.

- Consistent High-Quality: The bit is made of WC-CO Alloy, and 100% made by our own factory to ensure consistency, you can expect that every bit we produce performs exactly the same.