The cutting diameter of the router bits refers to the size of the cutting surface. Choosing the right diameter is important to ensure efficient cutting and a smooth finish. Smaller diameters are best for detailed work, while larger diameters are better for roughing out material quickly.

BUYING GUIDE

How To Choose Solid Carbide Spiral Router Bits

In the dynamic world of DIY and woodworking, selecting the right router bit is crucial for project success. However, with so many options, it can be daunting, especially for beginners.

We delve deeper, exploring how to choose the perfect router bit for your project's unique needs. Whether you're embarking on your first woodworking journey or you're a seasoned pro, we hope that our guide is packed with valuable insights and practical advice.

1. WORK MATERIAL

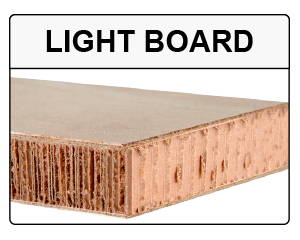

The material being cut is a critical factor in determining the type of router bits to use. Most of our bits are able to cut many different types of material, but, like anything, certain bits handle each material better than others.

Click on the material below to see which router bits are best suited for your project.

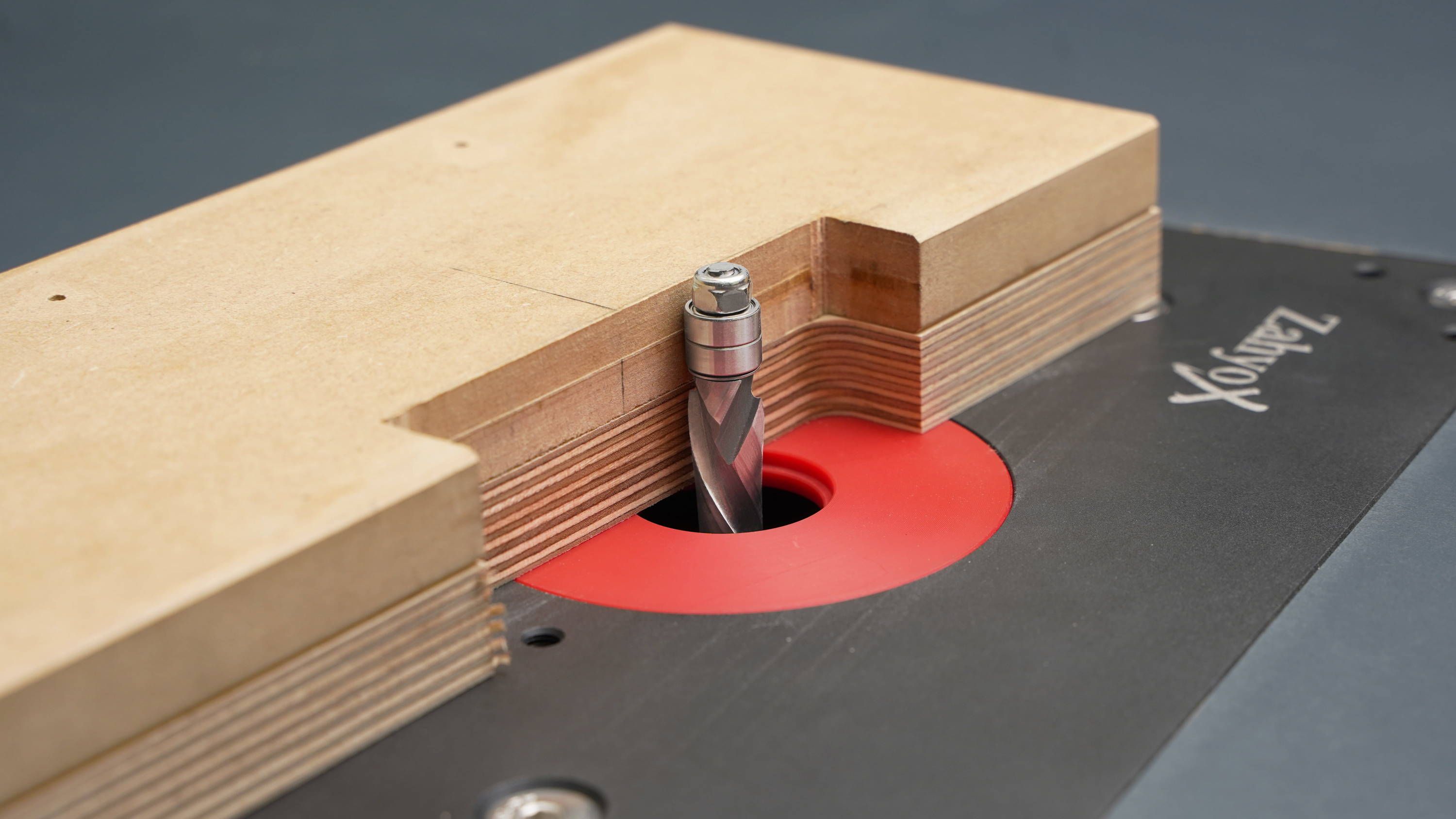

2. MACHINE USED

Choosing a router bit that's compatible with your specific type of machine – be it a router table, handheld router, or CNC router – is crucial for both optimal performance and safety. The right match ensures smooth operation, precision in your work, and extends the life of both your bits and machinery.

CNC SOFTWARE TOOL FILE DATABASE - Save your work time by importing a utility database of default values.

3. WORK TYPE

Whether it's the intricate art of engraving, the precision of grooving and cutting, the finesse in trimming and profiling, or the accuracy required in template and pattern work, each operation demands a type of router bit designed for the project.

For projects that involve cutting or grooving in wood, opt for spiral bits. These bits are specifically designed for creating precise grooves and clean cuts.

For detailed engraving or lettering projects, V-groove or engraving bits are ideal. Their sharp and slender design allows for the creation of fine lines and intricate details.

For trimming and profiling projects, flush trim router bits are the go-to choice. deal for creating smooth, consistent edges, flush trim bits are perfect for tasks like aligning laminate or veneer edges, or for template-guided shaping.

If your project involves precise cutting along a predetermined template or pattern, template bits or bearing-guided bits are the tools to use. They guarantee accurate movement along the template to achieve the desired shape.

For surfacing projects that need planing and smoothing of large wood surfaces, select spoilboard surfacing bits with a larger cutting face.

4. SPECIFICATION

Geometry

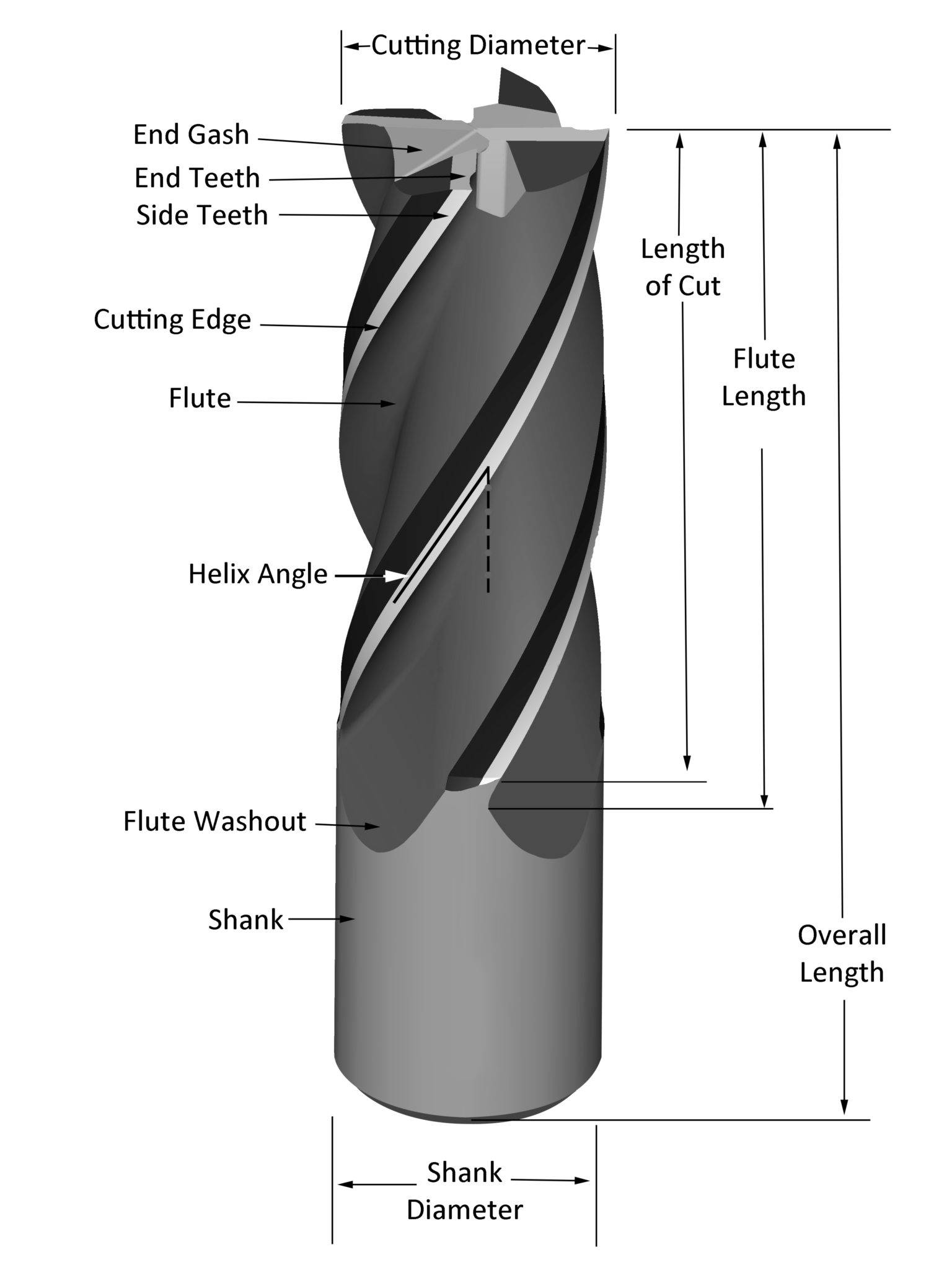

Cutting Diameter (CD)

Shank Diameter (SD)

The shank diameter is the width of the shank – the non-cutting end of the tool that is held by the tool holder. This measurement is important to note when choosing a tool to ensure that the shank is the correct size for the holder being used. Shank diameters require tight tolerances and concentricity in order to fit properly into any holder.

Length of Cutting (CL)

The total measurement of the functional (sharp) cutting depth, this excludes any Flute Washout, crucial for determining the maximum depth a bit can safely cut in a single pass.

Overall Length (OAL)

The total measurement from one end of the end mill to the other, from the top (cutting end) to the bottom of the shank. It is crucial as it affects the bit's compatibility with the router and the reach for deeper cuts, ensuring safe and effective operation.

Flute Count (FL)

The number of flutes on an end mill affects its cutting performance. End mills with fewer flutes are more rigid and can remove material faster, while end mills with more flutes provide a better finish.

Helix Angle

The cutting edge angle measured from the centerline of the end mill to a straight line tangent along the cutting edge. A larger angle results in smoother cuts and better chip ejection, reducing heat and wear.

End Teeth, Side Teeth, End Gash

End Teeth – The teeth or cutting edges at the very top of the end mill, also known as axial teeth.

Side (Peripheral) Teeth – The teeth or the cutting edges on the side of the end mill, also known as radial teeth.

End Gash – the pockets on the end of the end mill that create the axial (end) teeth.

Rotation

Just remember: down-cut bits cut away from your tool, and up-cut bits cut towards it. Compression router bits are a combination of down-cut and up-cut bits. The tip and first ⅛ – ⅝ inch is an up-cut, while the rest of the bit is a down-cut.

- DOWN-CUT

- UP-CUT

- COMPRESSION

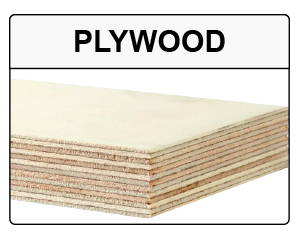

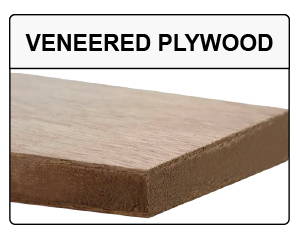

✓ Grooves in tearout-prone materials like highly figured wood, plywood, and other veneers

✓ For clean edge on the tool-side of your stock

✓ Cutting small parts on the CNC

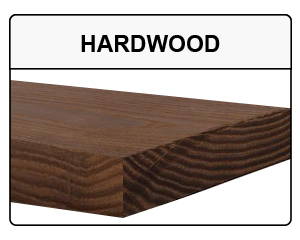

✓ Grooves in straight grained hardwoods like maple, walnut, or oak

✓ For clean edges on opposite side of your stock from the tool

✓ Plunge cutting

✓ Through cuts in harwoods, softwoods, plywood, melamine, and other veneers

Coating

ZahyoX operates our own PVD (Physical Vapor Deposition) coating work center. We provide you with unique coatings for their specific application, we developed X-Series, Y-Series and Z-Series for wood cutting, metal cutting and aluminum machining to truly maximize the performance achievable with ZahyoX cutting tools.

- X- Series

- Y-Series

- Z-Series

X-Series Coated

PVD nACo Coating, Designed for Wood Cutting.

3800 HV

high hardness

0.25

900°F

Max working temperature

Y-Series Coated

PVD TiAlN Coating, Designed for Metal Cutting.

3400 HV

high hardness

0.25

1300°F

Max working temperature

Z-Series Coated

PVD ZrN Coating, Specifically for Machining Aluminum

2400 HV

high hardness

0.30

1300°F

Max working temperature

Machining parameters

- Feed & Speed calculator

- tool datebase

FAQS

Mastering Precision

OUR BEST SELLERS

Vouched By 2,000+ Previous Buyers

Take a look at what's hot: Check out the tools woodworkers are choosing for their projects.