S1809 PRO - Compression nACo Coated Spiral Router Bit - 2Flutes - 1/8 SD - 1/8 CD - 1/2 CL - 2 OL - 1/8 UCL

S1809 PRO - Compression nACo Coated Spiral Router Bit - 2Flutes - 1/8 SD - 1/8 CD - 1/2 CL - 2 OL - 1/8 UCL

Available in stock

| Rotation | Compression | Coating | nACo |

|---|---|---|---|

| Shank Diameter | 1/8" | Router Bits Types | 1/8" Shank Spiral Bit |

| Cutting Diameter | 1/8" | Product Series | X-Series |

| Cutting Length | 1/2" | Cutting Edge Type | Solid Carbide |

| Overall Length | 2" | Measurement | Imperial |

| Flutes | 2 | Machinery Type | Handheld Router, Router Table, CNC Router |

| Material | Hardwoods, Softwoods, Laminate, Melamine, Plywood, MDF, Chipboard, Foamcore, Light Board, Aluminum Foamcore, Veneered Plywood, Particle, OSB, Solid Surface Material, Plastic, Acrylic | ||

| Rotation | Compression |

|---|---|

| Shank Diameter | 1/8" |

| Cutting Diameter | 1/8" |

| Cutting Length | 1/2" |

| Overall Length | 2" |

| Flutes | 2 |

| Coating | nACo |

Why Choose Spiral Router Bits Instead of Straight Bits?

- Spiral router bits combine a shearing action with an augering action for chip clearance. This dual action not only produces a clean and accurate cut but also efficiently clears chips from the cut area, enhancing the overall cutting experience.

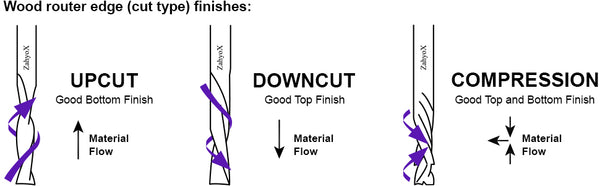

What is Compression (Up-Cut & Down-Cut) Bits

- Features: Compression bits combine the features of both up-cut and down-cut bits. The top part of the bit is designed to be down-cut, improving the top edge finish, while the bottom part is up-cut, enhancing the finish on the bottom side of the material. This up-cut down-cut action is what leaves a sharp, clean edge on both edges of your workpiece.

- Applications: The preferred bit for cutting laminated materials or any situation where both sides of the material are visible and require a fine finish.

- Considerations: To fully benefit from a compression bit, it's crucial to make the initial cut deeper than the length of the up-cut flutes to prevent any tear-out or chipping on either side of the material.

What is nACo Coating?

nACo, or nano-composite coating, is a micro-thin ceramic coating applied to cutting tools. Zahyox PRO-Series bits feature a nACo coating with extreme hardness and heat resistance. With a blue-tinted coloring, nACo enhances their performance and durability in router tooling.

- Sharpness Retention: Maintains cutting edges razor-sharp for precise and clean cuts.

- Reduced Friction: Features an extremely low friction coefficient of 0.25, minimizing tool wear and facilitating smoother operations.

- Heat Resistance: Can withstand up to 900°F, protecting tools from heat damage during intense cutting tasks.

- Enhanced Durability: Delivers a hardness of 3800 HV, which increases resistance to wear and extends 3 times longer tool life.

Why Choose ZahyoX 1/8 inch Shank Router Bits?

- Geometry Specs: 1/8" Cutting Diameter, 1/8" Shank, 1/2" Cutting Length, 2" Overall Length, 2 Flutes, Compression Rotation, Nano Coated.

- Trusted Brand: ZahyoX is an industrial manufacturer, making solid carbide material and solid carbide router bits is our sole business for over two decades, we make our products like treating art.

- Perfected Geometry: The geometry design has been iterated hundreds of times to ensure a perfect balance between tool life and cutting efficiency. We run our bits systematically on various machines and materials to test the performance of each iteration.

- X-Series: X-Series is one of our signature product lineups and bestselling for wood cutting, it is made by our own PVD process of Nano Composite Titanium Aluminum Silicon Nitride which provides highest hardness of 3800 HV, extremely low friction of 0.25, at 900°F max working temperature. The coating provides 3 times longer tool life for wood cutting performance.

- Consistent High-Quality: The bit is made of WC-CO Alloy, and 100% made by our own factory to ensure consistency, you can expect that every bit we produce performs exactly the same.